What is a piston valve?

A piston valve is a device that is used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder.

Piston valves are used for fully open or fully closed for on/off regulation on steam, gas, and other fluid services.

These valves are mostly used on fluids that cause excessive seat wear.

Piston valves are mostly actuated (operate) manually, but sometimes other actuation modes (operate) such as hydraulic and electric are used.

Piston valves are usually used where the valve body is permanently installed to reduce maintenance. Piston valves are not designed for throttling applications and they must be used in fully opened or closed positions. When the valve is fully opened, only the bottom face of the piston is exposed to fluid and the rest of the body is protected by the upper sealing rings. So the sealing surfaces are protected from erosion by the fluid flow.

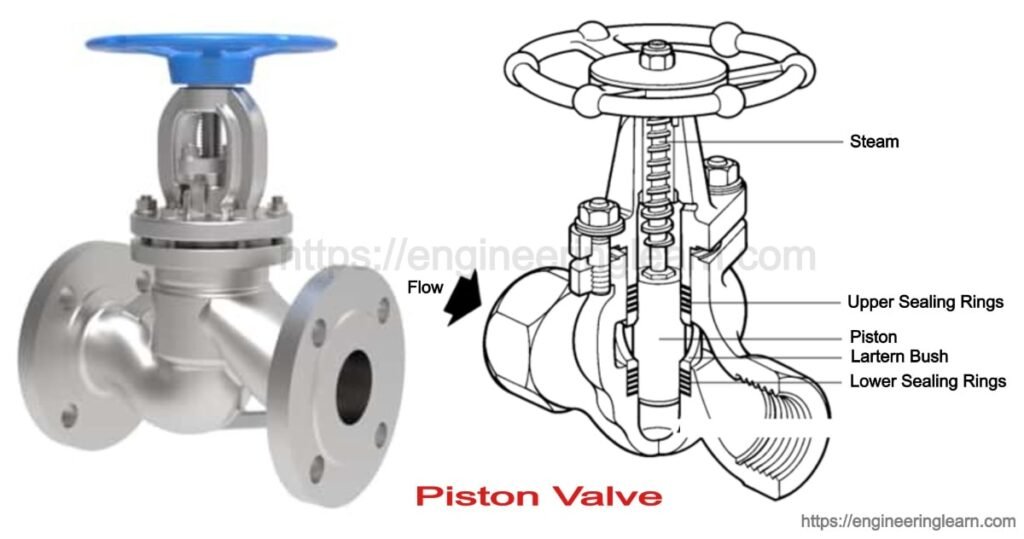

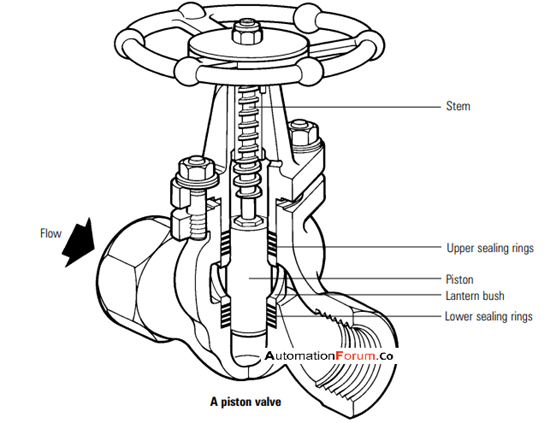

What are the parts of piston valves and how are they constructed

Piston valve parts

- Body

- Bonnet

- Piston

- Valve rings

- Lantern bush

- Spindle

- Gland

- Packing

- Handwheel

- Yoke bush

- Bonnet stud

- Gland eyebolt

How does a piston valve work?

The construction of a piston valve is similar to a globe valve and they are used to shut off and regulate.

These valves provide positive shut-off.

The shut-off assembly comprises the metal piston, two resilient valve rings, and a metal lantern bush.

The sealing surface consists of the outer vertical surface of the piston and the corresponding inner surfaces of the sealing rings.

This provides a sealing surface compared to the globe valves of conventional design.

يوفر هذا سطحًا مانعًا للتسرب مقارنة بصمامات الكرة الأرضية ذات التصميم التقليدي

At the beginning of the opening, a displacement uncovers the small flow section. Which controls the low rate of flow.

Most automatic valves are of double disc type, the double-disc design can be used to equalize the pressure across the disc and it can be varied to change the flow characteristics through the valve or to change the operation of the valve such as by decreasing the response time of the valve’s action.

A piston balance valve allows the force exerted across the seating area to be as equal as possible while being directed in the opposite direction. The double-disc arrangement has the flow coming from the left. In the closed position, the fluid pressure would press against the bottom of the top disc and against the top of the bottom disc equalizing flow pressure.

Even when the valve is open there is an equalizing force that gives the valve a smooth operation.

عندما يكون الصمام مفتوحًا ، توجد قوة موازنة تمنح الصمام تشغيلًا سلسًا

What are the types of piston valves?

Balanced and unbalanced are the two types of piston valves.

Balanced valves are used in high-pressure service

and unbalanced ones for low-pressure service.

There are two types of pistons designs available regulating the type and the normal.

In the regulating type, the bottom part of the piston is tapered to have a throttling effect.

The sealing rings are the heart of piston valves.

What are the applications of piston valves?

- thermic fluid

- fatty acids

- gases and hazardous fluids

- steam service

صمام المكبس Piston Valve – أنا مهندس كيميائي (i-chemeng.com)